A new discovery.

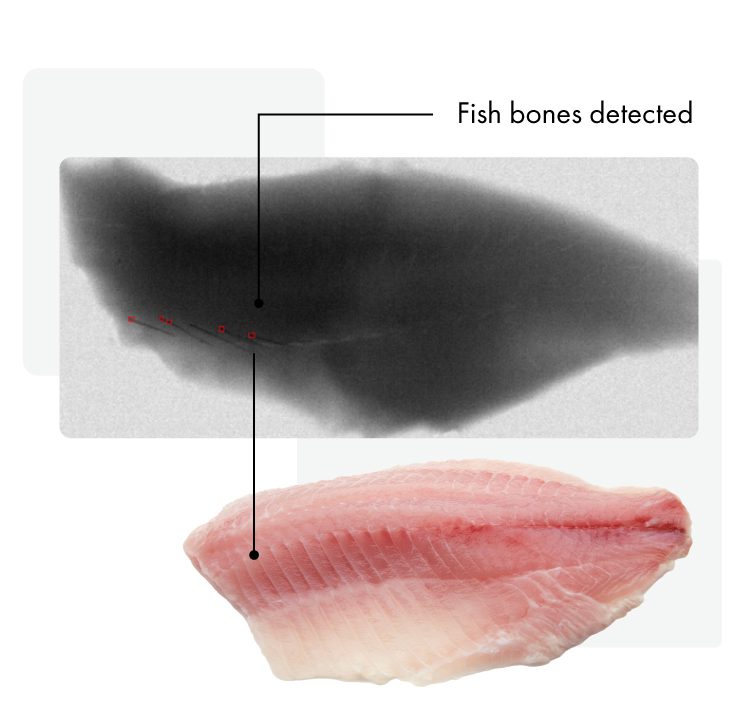

Recently, during an experiment conducted in our showroom, we made an intriguing discovery: our x-ray machine was not only capable of detecting foreign objects in our products, but it could specifically identify fish bones with remarkable precision. This breakthrough not only demonstrates the sophistication of modern x-ray technology but also highlights its role in food safety.

How do x-ray machines work?

In the stringent world of food production, ensuring the safety and quality of products is high priority.

X-ray machines designed for food inspection operate on the same basic principles as those used in medical imaging. By measuring the different densities in the product, they can detect foreign materials within food products. This includes a wide range of contaminants such as metal, glass, stone, plastic, and even bone fragments.

The process begins with the product passing through a conveyor belt beneath the x-ray emitter. As the x-rays penetrate the food, they are absorbed differently by various materials. Dense materials, like bone or metal, absorb more x-rays, appearing as darker areas on the resulting image. On the other hand, less dense materials, such as flesh or packaging, allow more x-rays to pass through, appearing lighter.

Advanced algorithms analyze these images, flagging any anomalies for further inspection. Some x-ray machines come with automatic rejection systems to keep your production lines running smoothly as contaminants are detected.

Why do food producers use x-ray machines?

1. Enhanced safety

Consumer safety is priority number one. By detecting foreign objects, x-ray machines help prevent contamination and reduce the risk of injury or illness for consumers.

2. Compliance with regulations

Many food safety regulations and third-party certifications mandate thorough inspection processes to ensure compliance. X-ray technology offers a reliable method for meeting these standards and avoiding costly recalls or penalties.

3. Retailer requirements

More retailers are bringing strict product requirements to ensure consumer safety with contaminant-free foods in their stores. Costco is one example of retailers with audit requirements for producers to utilize detection equipment like x-ray machines.

4. Quality assurance

Beyond safety, x-ray inspection can also identify defects in products, such as missing components or improperly sealed packaging, thereby maintaining overall product quality.

5. Increased efficiency

X-ray machines operate quite fast, capable of inspecting hundreds of products per minute without compromising accuracy. This efficiency minimizes production delays and keeps the supply chain running smoothly.

6. Versatility

X-ray technology is adaptable and can be customized to accommodate various food types, sizes, and packaging formats, making it suitable for a wide range of applications across the food industry.

Interested in trying an x-ray machine?

At our facility, we have metal detectors and x-ray machines ready for testing. Not sure if your application can be detected? Like our experiment with fish bones, you can bring in your product to our showroom and test it with our machines. We’re committed to ensuring safety and quality in every product that reaches your customers’ tables.

Wrapping up

X-ray machines have revolutionized food production by providing a robust solution for detecting contaminants and ensuring compliance with rigorous safety standards. As the food industry continues to evolve, embracing cutting-edge technologies like x-ray inspection will be essential in safeguarding consumer trust and promoting a culture of transparency and excellence.

Share this post

Have a project in mind?

Get in touch today for a custom quote.