Understanding shrink bags.

Shrink bags are essential in the food industry for a variety of reasons. They provide a clean, form-fitted look, enhancing the presentation of your products. We offer durable bags made with less plastic, free from chlorine and PVDC for a more sustainable solution.

The process is straightforward: vacuum seal your product, apply heat (in a dip tank or shrink tunnel), and watch as the bag shrinks to a sleek, protective fit. But with several types of shrink bags available, it can be challenging to determine which one is best for your specific needs. This guide will differentiate the various shrink bags we offer and help you make an informed decision.

Standard shrink bags.

Features and benefits:

Thickness: 45 – 50 microns

Barrier properties: High oxygen and water vapor barrier

Printing and sealing: Available with flexographic printing with up to 10 colors per side, with side seal, curved or straight bottom seals.

Durability: Strong, high-barrier pouches that maximize shelf life.

Application:

Standard shrink bags are perfect for a wide range of boneless fresh and frozen products. They are particularly beneficial for producers looking to enhance shelf life and sustainability while maintaining a sleek product presentation for processed meats, cheese, alternative proteins, and fresh red meat.

High abuse shrink bags.

Features and benefits:

Thickness: 60 microns.

Barrier properties: High oxygen and water vapor barrier with higher puncture resistance for products that need more protection.

Printing and sealing: flexographic printing with up to 10 colors per side, with curved or straight bottom seals, and taping for automated equipment.

Application:

High abuse shrink bags are designed for products that require an extra level of puncture resistance and durability, particularly those undergoing pasteurization. They are the go-to choice for smoked and cured meats, picnic hams, hard cheeses, and other processed products.

Bone guard shrink bags.

Features and benefits:

Thickness: 95 or 110 microns.

Barrier properties: High oxygen and water vapor barrier with the highest puncture resistance.

Printing and sealing: flexographic printing with up to 10 colors per side, with curved or straight bottom seals, and taping for automated equipment.

Application:

Bone guard shrink bags are specifically designed for bone-in products, providing maximum puncture resistance without the need for patches or bone guard cloth. These bags are ideal for items like racks of ribs or bone-in cuts that require robust packaging to prevent leakage during transport and storage.

Breathable shrink bags.

Features and benefits:

Thickness: 55 – 60 microns.

Barrier properties: Low oxygen barrier to let products breathe with high water vapor barrier.

Appearance: Available in ultra-clear, opaque white, or cream, or bags can be customized with up to 10 colors per side with flexographic printing.

Printing and sealing: Straight or curved bottom seals, and options for taping for automated equipment.

Application:

Breathable shrink bags are also known as poultry shrink bags. These bags are tailored for fresh products that need to breathe in refrigerated environments. They are particularly effective for fresh chicken, turkey, duck, and fish, ensuring optimal freshness and quality whether stored fresh or frozen.

How to shrink seal products.

Materials:

- Shrink bags.

- Chamber vacuum sealer.

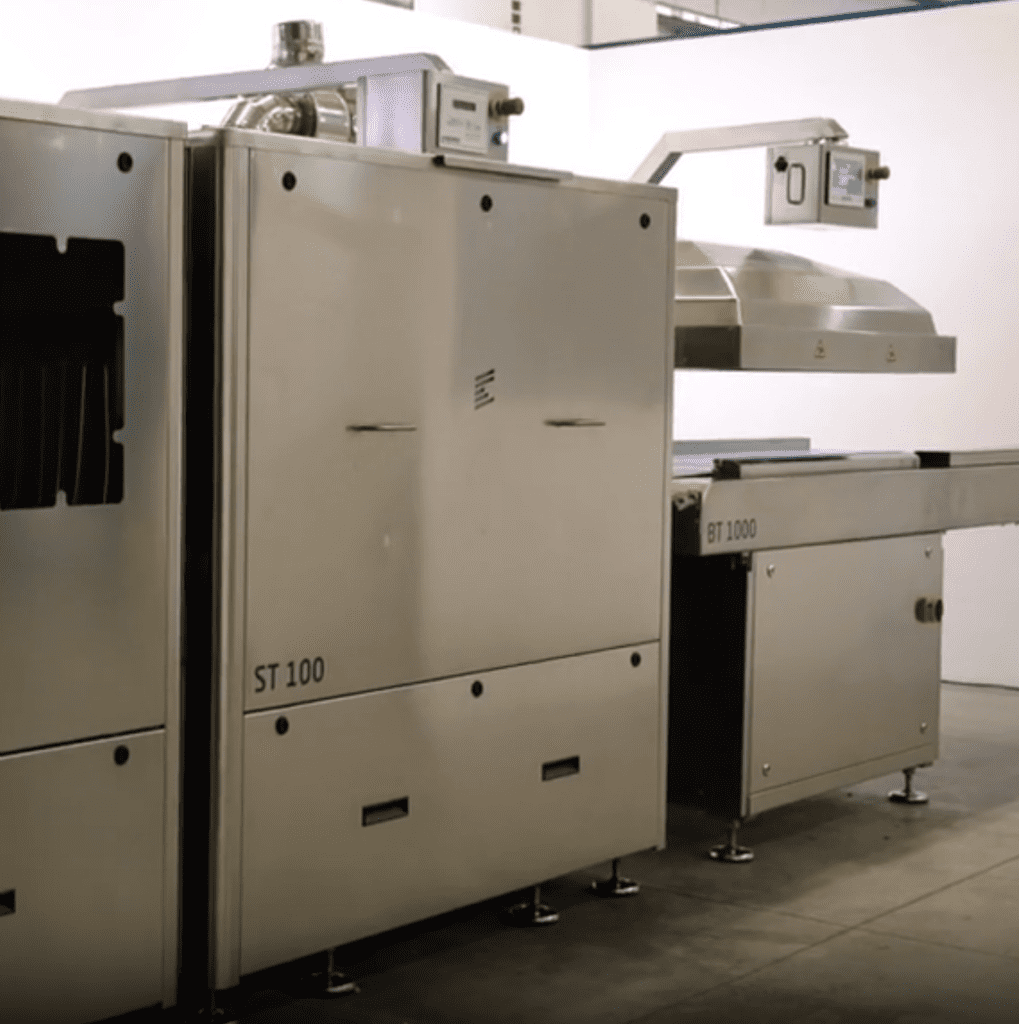

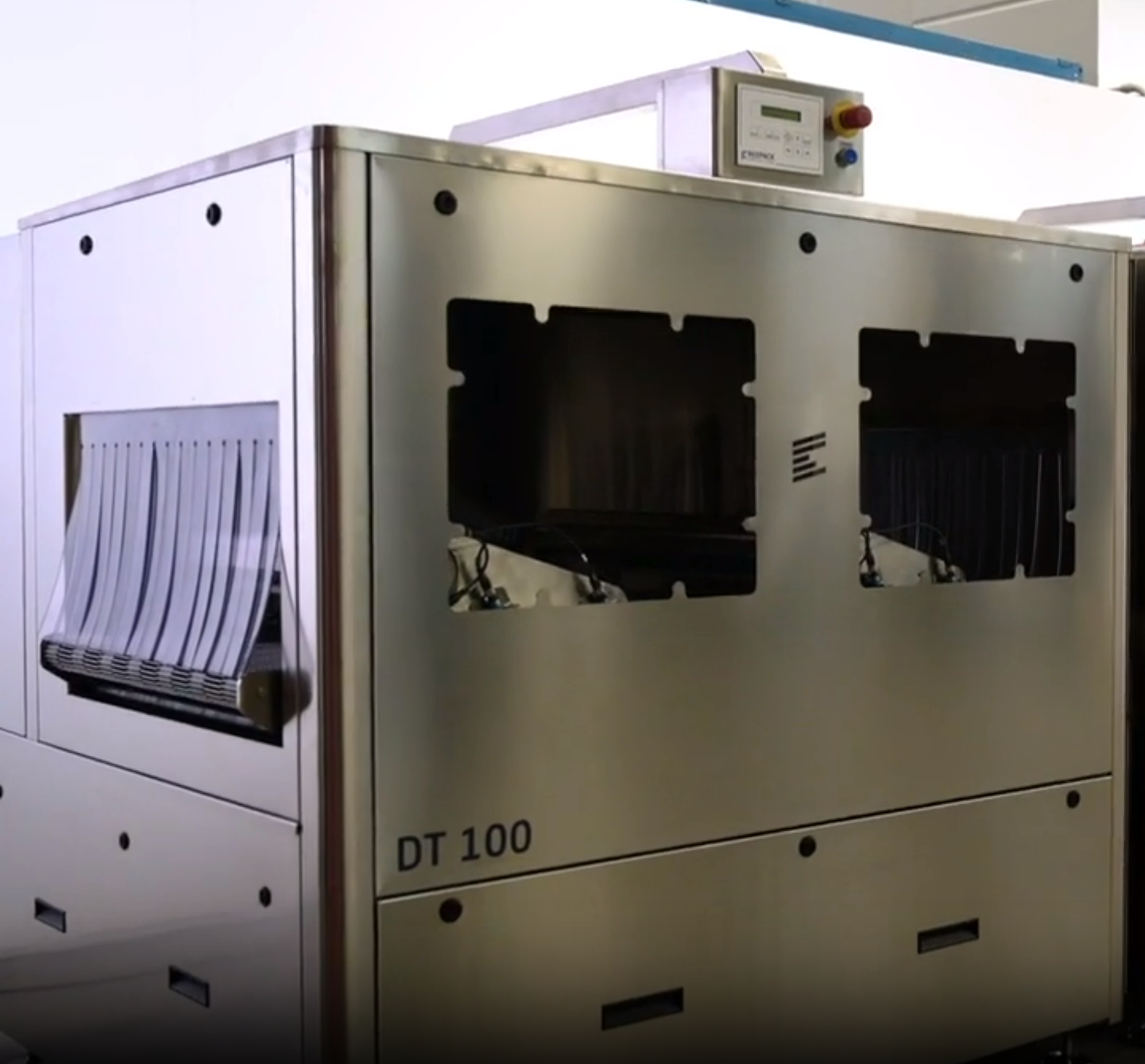

- Dip tank or shrink tunnel with drying tunnel (optional for automation in high production environments).

Step 1: Insert the prepped product into the shrink bag.

Step 2: Seal the product with a vacuum sealer to remove air inside the package.

Step 3: Shrink the bag with heat in a dip tank or shrink tunnel.

Step 4: (Optional) Use a drying tunnel to remove excess moisture. To further increase shelf life, bags can be put through a chilling unit at this step for rapid cooling.

Step 5: Check for a tight seal and that there are no leaks before moving to storage.

Wrapping up.

Choosing the right shrink bag is crucial for maintaining the quality and presentation of your food products. Standard shrink bags offer a sustainable option for boneless products, while high abuse shrink bags provide the necessary durability for processed meats. Bone guard shrink bags are essential for bone-in products, and breathable shrink bags are perfect for fresh poultry. By understanding the unique features and ideal applications of each type, you can choose the best shrink bag to meet your product needs and ensure maximum shelf life and consumer appeal.

Share this post

Have a project in mind?

Get in touch today for a custom quote.