Protect your consumer. Protect your brand.

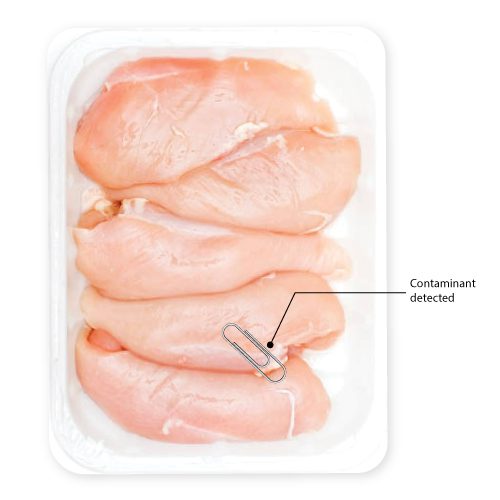

There’s no greater fear in the food processing world than a consumer opening your product and finding a contaminant like metal shavings or glass shards mixed into their food – or worse, your customer biting into one. Physical contaminants can cause injuries, create choking hazards, or pose health risks, and it’s a major concern in the safe manufacturing of foods.

In the fast-paced world of manufacturing and packaging, ensuring product quality, safety, and compliance is incredibly important. X-ray machines, metal detectors, and magnet separators play a vital role in safeguarding products and preventing potential hazards. They contribute to a robust packaging line security system and help food producers meet quality assurance standards set by regulatory agencies.

1. Metal detectors for packaging lines.

As products move along the conveyor belt, metal detectors use electromagnetic fields to detect the presence of any metal contaminants that have made their way into the product. When a metal object is identified, the metal detector triggers an alarm or activates a rejection system to remove the contaminated product from the production line. Metal detectors minimize the risk of injury or damage during food production. In some cases, metal detectors are a requirement to hold certain food safety certifications.

2. Magnet separators to remove contaminants.

Magnet separators are designed to detect and remove magnetic contaminants from the product stream in a packaging line. These contaminants can include ferrous materials like iron or steel. Magnet separators utilize powerful magnets, strategically positioned along the conveyor belt, to attract and capture magnetic particles. By effectively removing these contaminants, magnet separators prevent potential product damage, equipment malfunction, and ensure the purity and integrity of the packaged goods.

3. X-ray machines for enhanced contamination detection.

These machines use X-ray technology to scan products, detecting a wide range of contaminants beyond just metal. X-ray inspection can identify foreign objects such as glass, stones, plastic, or rubber, which may pose potential risks to consumers. Additionally, X-ray machines can detect inconsistencies in product dimensions, missing components, or improper fill levels. By conducting a comprehensive inspection, X-ray machines ensure product safety, quality, and compliance with regulatory standards.

Benefits of packaging contaminant detection systems in the food industry:

Product safety

Ensure product safety by detecting and removing contaminants such as metal fragments, foreign objects, or magnetic particles. This minimizes the risk of consumer harm and helps meet regulatory standards.

Quality assurance regulations

Manufacturers can maintain consistent product quality, preventing contaminated or compromised items from reaching the market. Regulatory bodies, such as the Food and Drug Administration (FDA) and other industry-specific organizations, establish strict guidelines for product safety and quality. Compliance with these regulations is essential for ensuring product safety and avoiding penalties.

Operational efficiency

X-ray machines, metal detectors, and magnet separators can all be directly integrated into a high-speed packaging line and enables automated and rapid detection of contaminants. This enhances production efficiency by reducing manual inspection needs, increasing throughput, and streamlining the overall packaging process.

Brand reputation

A single product recall or contamination incident can have severe consequences for a company's reputation. By integrating security measures into the packaging line, manufacturers proactively prevent contaminated products from reaching the market, minimizing the risk of consumer harm and negative publicity. By prioritizing product safety and quality, companies can instill confidence in their brand and maintain long-term customer loyalty.

Wrapping up, the integration of X-ray machines, metal detectors, and magnet separators into packaging lines is indispensable for ensuring product quality, safety, and compliance. These advanced security measures offer a comprehensive solution to mitigate risks, protect consumers, and maintain the highest standards in the fast-paced world of manufacturing and packaging.

Want to learn more about detection equipment?

Share this post

Have a project in mind?

Get in touch today for a custom quote.