Flexible plastic food packaging.

As the demand for effective and sustainable packaging grows, flexible plastics are taking center stage in the food industry. Whether you’re a food processor or manufacturer, understanding the nuances of flexible plastics can help you make informed decisions that benefit both your products and the environment.

The essentials of flexible plastics

Flexible plastics are adaptable materials used in packaging solutions like bags, pouches, and wraps. They are designed to be lightweight, durable, and versatile, making them ideal for a wide range of food products. The key types are:

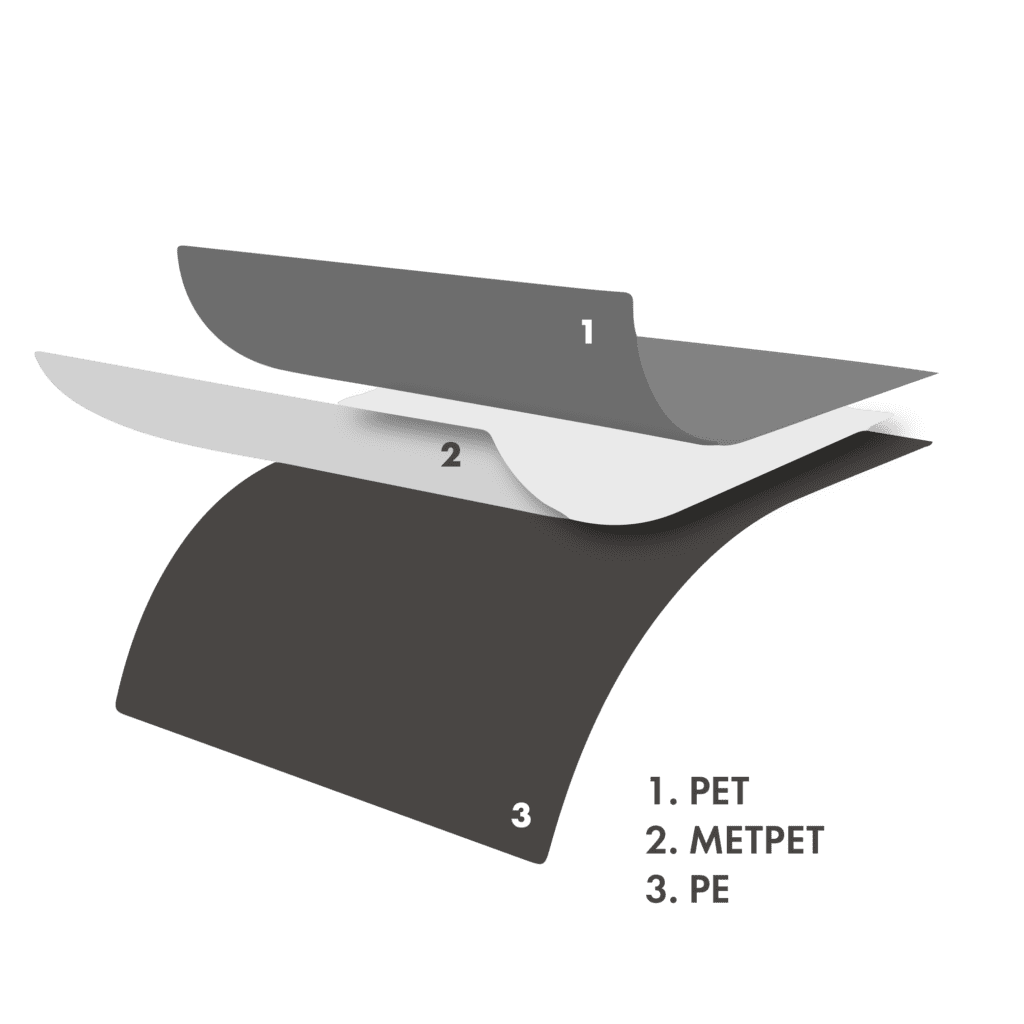

Multi-material structures

These combine various materials to create superior barriers against moisture, oxygen, and contaminants. These are often the best options for extending shelf life and keeping foods out of the landfill. Recyclability of these materials depends on the municipality, but some facilities like Recycle BC will pelletize them and turn them into engineered fuel.

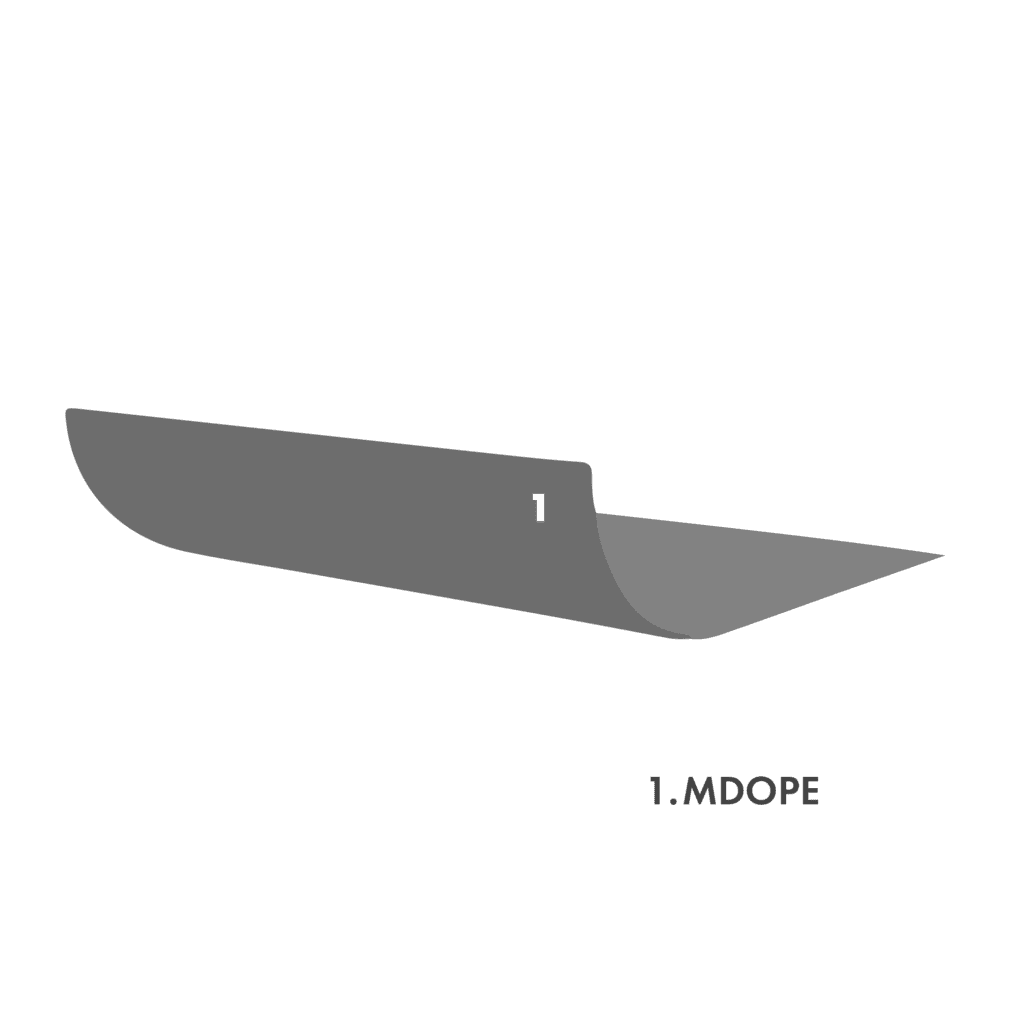

Mono-material structures

Made from a single polymer type, these are theoretically easier to recycle in the waste stream since they don’t require delamination, but they are currently recycled in the same way as multi-material structures due to the lack of appropriate recycling infrastructure in place. While they’re not accepted in the blue bin for recycling, they are becoming increasingly popular as technology develops.

What food producers need to consider when choosing packaging.

1 . Shelf life

Food waste is a $1 trillion problem worldwide with 1.3 billion tons of food being wasted yearly, we recommend solutions that are optimized to keep your product as fresh as possible for as long as possible. While multi-material packaging excels here, mono-materials are advancing to provide similar benefits through improved designs.

2 . Barrier performance

This is especially important when modified atmosphere or vacuum is used to preserve products. Packaging shields food from moisture, oxygen, and contaminants to ensure freshness. Traditional multi-material solutions are known for their excellent barrier properties, while new mono-materials may offer less protection than standard packaging.

3 . Mechanical strength

Flexible packaging needs to withstand handling and shipping without tearing. Often, food producers have products sent back to their facilities due to breakage between their production facilities and the retail environment, which can cause hundreds of thousands of dollars of losses and a large amount of food waste.

4 . Food safety

Safety is paramount. Flexible plastics must comply with regulations to prevent harmful chemicals from migrating into food. Mono-materials are being developed to meet these safety standards without the complexity of multi-material layers to make them comparable, but the source of your packaging can also be important.

5 . Processing compatibility

If you’re looking into transitioning to mono-materials or to more durable packaging to protect your foods, it might require adjustments in your packaging processes and machinery. It’s crucial to work with suppliers who can guide you through integrating these new materials into your production line.

Action steps for food producers

Assess your needs

Evaluate your product's requirements for barrier protection, strength, and shelf life to determine which packaging best suits your needs.

Partner with suppliers

Collaborate with your packaging suppliers to explore innovative solutions and integrate new materials into your processes.

Design for the right end of life solution

Simplify your packaging design to enhance recyclability. Avoid complex multi-material structures where possible, unless it’s essential to keep your product fresh and protected.

Educate consumers

Clearly label your packaging with recycling information and educate consumers on proper disposal methods.

Stay informed

Keep up with the latest advancements in flexible packaging technologies and regulatory changes to continuously improve your packaging strategies.

Wrapping up.

Flexible plastics are crucial in modern food packaging, balancing performance and sustainability. For food processors and manufacturers, the shift towards mono-materials offers a promising path to reduce environmental impact while ensuring product quality and safety. By embracing these innovations, you can contribute to a more sustainable packaging future.

Contact our reps for more information on flexible packaging structures.

Share this post

Have a project in mind?

Get in touch today for a custom quote.