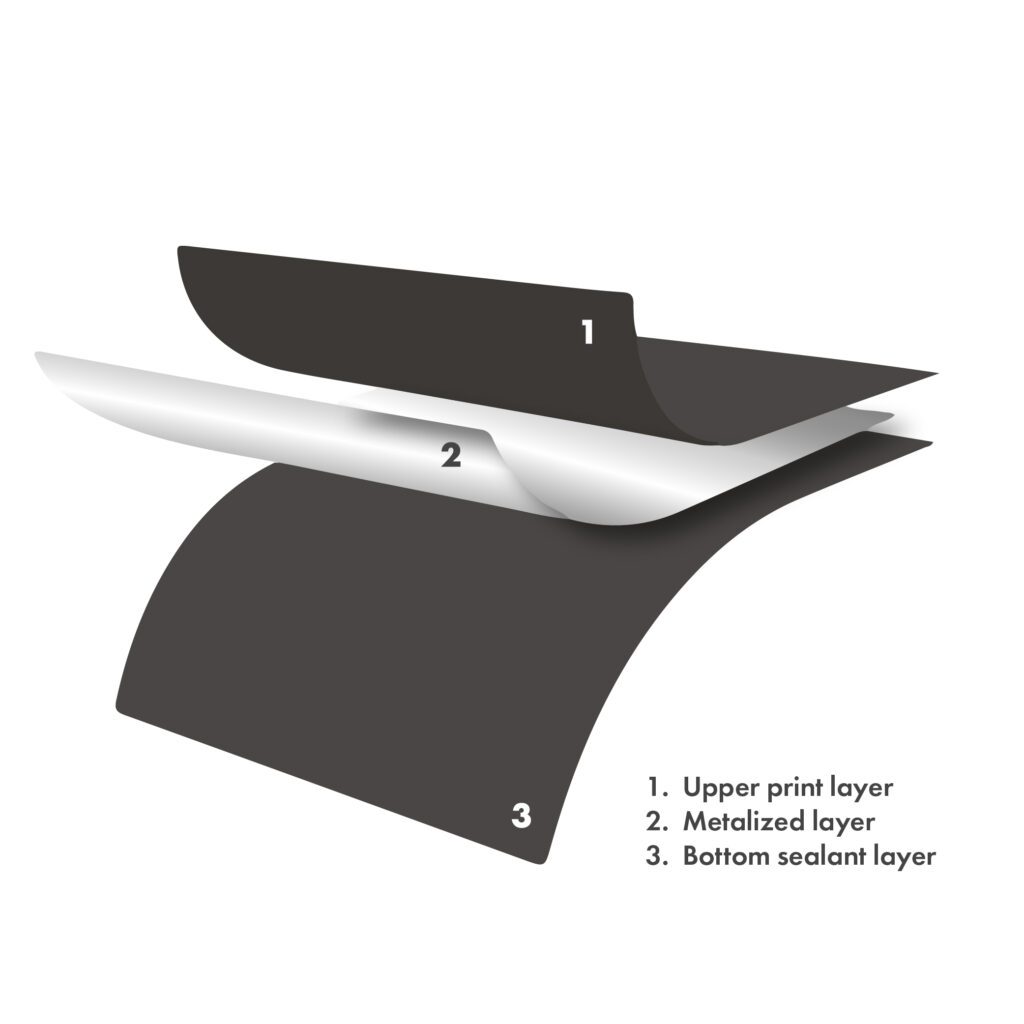

Metalized layers.

Flexible food packaging is a popular choice in the food industry because it’s a versatile, convenient, and cost-effective solution. One extremely common feature in flexible food packaging is a metalized interior layer, which is useful for a variety of reasons.

The metalized layer in flexible food packaging is typically made of a thin layer of aluminum (AL) or vacuum metalized polyester (VMPET, also known as METPET). This layer is laminated to the plastic during manufacturing between the interior sealing layer and the exterior printing layer. The metalized layer can also vary in thickness depending on your product requirements.

Why do companies add a metalized layer to food packaging?

1. Provides a barrier against oxygen and moisture.

Oxygen and moisture are two of the most common causes of food spoilage and can cause quality issues like discoloration, texture changes, and the growth of microorganisms. The metalized layer helps to prevent oxygen and moisture from entering the packaging, which can help maintain the shelf life and quality of the product.

2. Provides a better barrier against light.

Certain types of food like coffee, tea, and some snacks are sensitive to light and can become discolored or lose nutritional value if exposed to too much light. The metalized layer can help to block out light and prevent these issues from occurring.

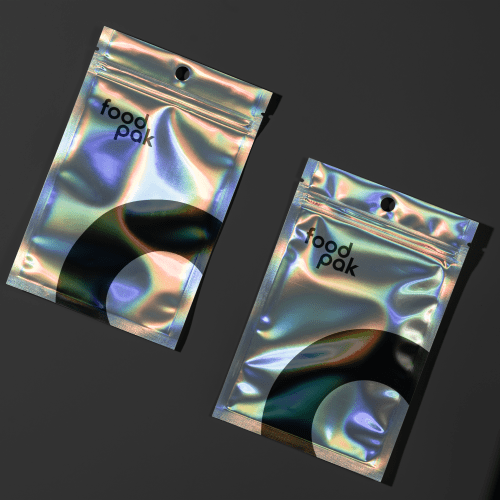

3. Create aesthetic metallic design features.

The metalized layer can help to create an eye-catching visual effect that can enhance the product's appeal. Using a semi-transparent printed layer, a metallic color effect can be incorporated onto the design to create golds, silvers, coppers, or other metallic colors on your packaging. Depending on your design, you can use this to create a completely metallic finish, or it can be used on individual design elements or text to help your product stand out the shelves.

How do I know if my product needs a metalized layer?

Requirements for packaging are going to be product specific, and there are a number of factors, such as ingredients, preparation, and storage, that might play a role in packaging. If you’re unsure of your product shelf life and requirements, you can consult with a food scientist or food lab in your area for more information.

Do I need aluminum or VMPET?

While the two structures are similar, they are slightly different in cost and barrier properties. Aluminum layers tend to be slightly more expensive than VMPET. Choosing one or the other will depend on both budget and the specific barrier requirements for your products, since they have differing water and oxygen transfer rates.

Wrapping up, the metalized layer in flexible food packaging has a few important functions, including a barrier against oxygen, moisture, and light, as well as providing aesthetic and marketing benefits. By choosing flexible food packaging with a metalized layer, food producers can help to extend the shelf life of their products and enhance their appeal to consumers.

Want to upgrade your packaging? Our reps can help you investigate options to add a metalized layer to your packaging.

Share this post

Have a project in mind?

Get in touch today for a custom quote.