What are Flow Wrappers?

When it comes to packaging products, a flow wrapper is a popular choice for many companies.

A flow wrapper is a type of horizontal form fill and seal (HFFS) machine that wraps products in a continuous sheet of film. The machine takes the product and feeds it into a tube of film that is then sealed.

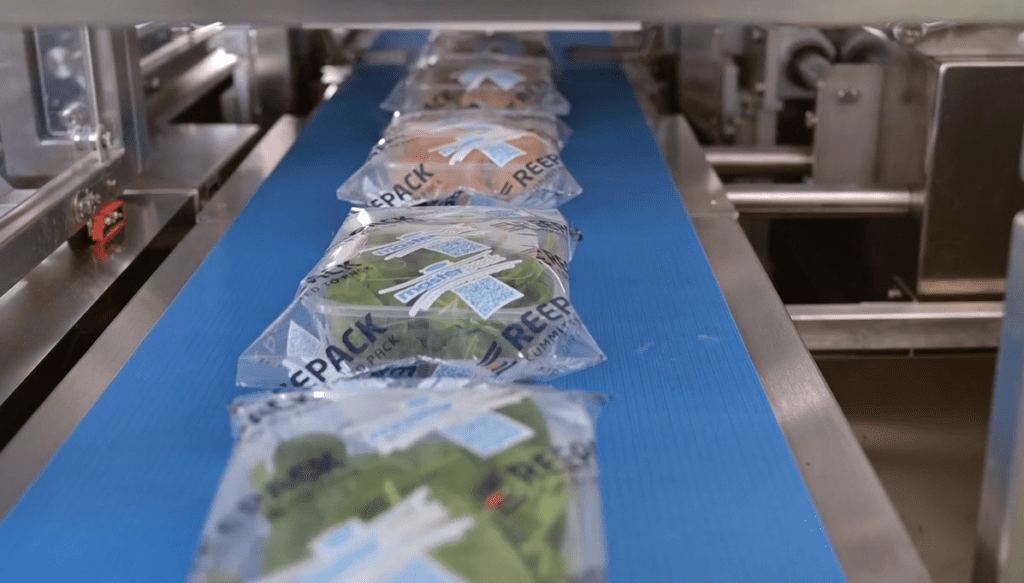

Flow wrappers are used to package a wide range of products, including food items like baked goods, produce, and snacks, as well as non-food items like medical supplies and toys.

How Does a Flow Wrapper Work?

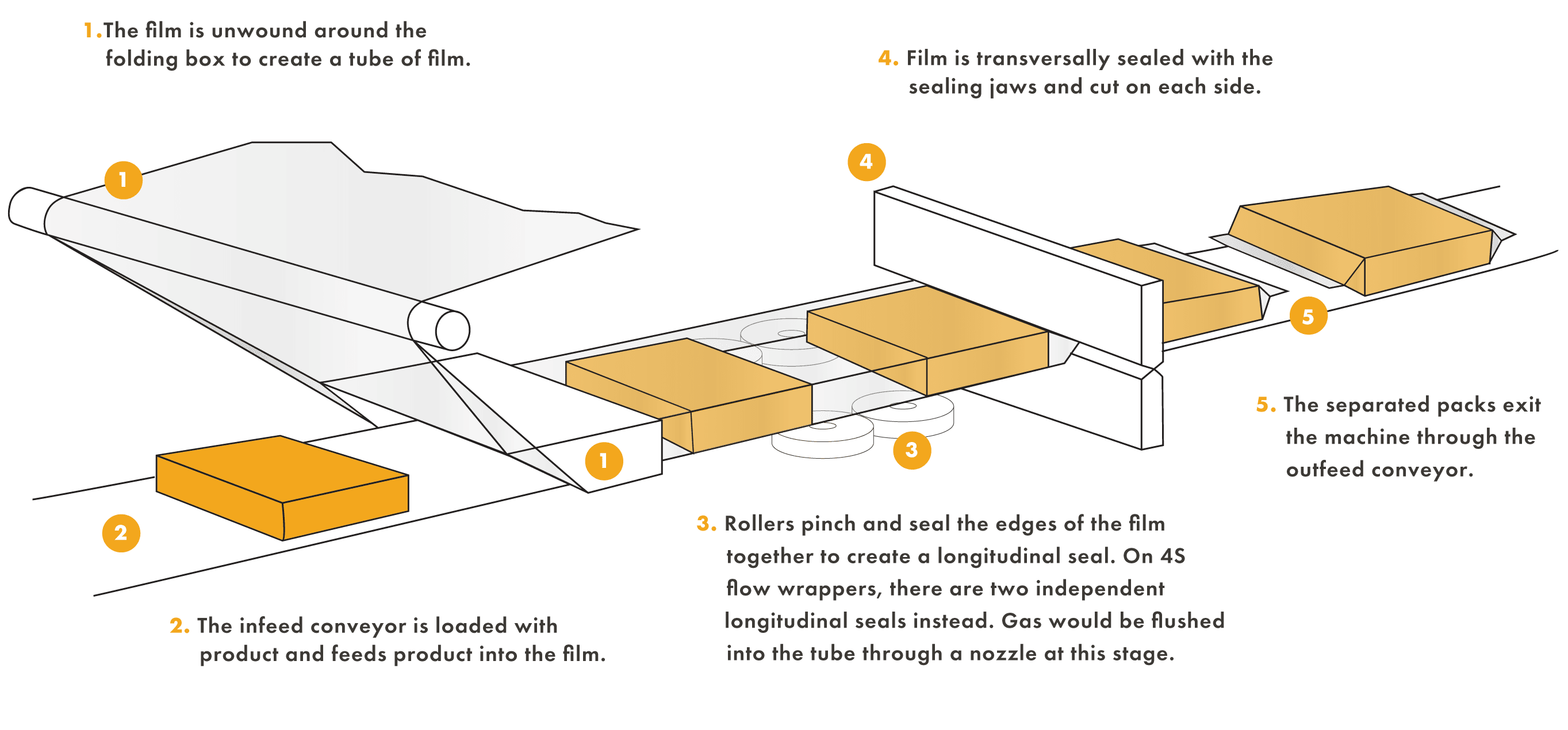

Flow wrapping machines consist of a product infeed conveyor, a film unwind section, a forming section, a sealing section, and a cutting section.

- The film is unwound around the folding box to create a tube of film.

- The infeed conveyor is loaded with product and feeds product into the film tube.

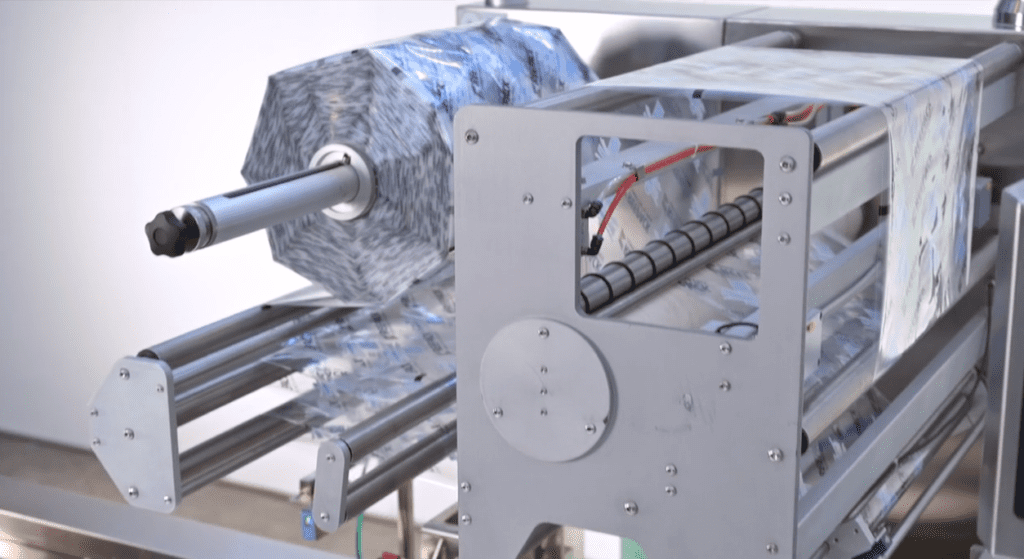

- Rollers pinch and seal the edges of the film together to create a longitudinal seal. Gas would be flushed into the tube through a nozzle at this stage if applicable.

- Film is transversally sealed with the sealing jaws and cut on both ends at the cutting station.

- The separated packs exit the machine through the outfeed conveyor.

The continuous nature of the machine with automatic packaging and sealing makes this a highly efficient solution for production facilities packaging large amounts of product.

There are various models with different speed and sealing capabilities. The right flow wrapper is matched with your product, the type of film, and your desired production output.

Benefits of Using a Flow Wrapper

High Speed Packaging

Flow wrappers offer high-speed packaging and an automated form, fill and seal process, ensuring rapid and efficient product packaging.

Cost-Effective

Flow wrap film can allow for a lower unit cost per package. In addition, automating the filling process allows for lower labour costs.

Extend Shelf Life

Flow wrappers create a tight seal and can be manufactured with a gas flush and high barrier film to increase product shelf life.

Customizable

Flow wrappers are manufactured to your exact product specifications. These units can handle various packaging materials, allowing for customizations like zig-zag cuts, hole punching, tear notches, and printed film alignment.

Packaging Line Integration

Flow wrappers seamlessly integrate into existing production lines, compatible with automated systems for streamlined packaging processes.

Flow Wrapper Packaging

Flow wrappers use flow wrap film to create the bags. This film can have a variety of structures, from standard clear film to high barrier to metalized. Flow wrap film can be fully printed, it can have a repetitive scatter print, or it can be stock film with a label applied.

Considerations for Using a Flow Wrapper

High Capital Investment: Flow wrappers are more expensive than other types of sealing equipment, such as impulse sealers, band sealers, or vacuum sealers. While they can save labour costs and can decrease unit costs for packaging, the price tag often doesn’t work for small to medium businesses.

Limited Product Flexibility: Flow wrappers work optimally when producing the same product at high speeds. While there is some flexibility across different runs with adjustable folding boxes, there are limits to the number of product sizes that can be accommodated after the machine is manufactured.

Share this post

Have a project in mind?

Get in touch today for a custom quote.